The case: B21ET with 531 head, B23 intake, 90s Mitsubishi exhaust manifold ported to T3 flange, A cam, 3 inch downpipe then 2.5 inch with no mufflers or cat and Kjet. The car has no electronics at all, so no knock sensors etc just a wideband

The question for turbo experts :

:

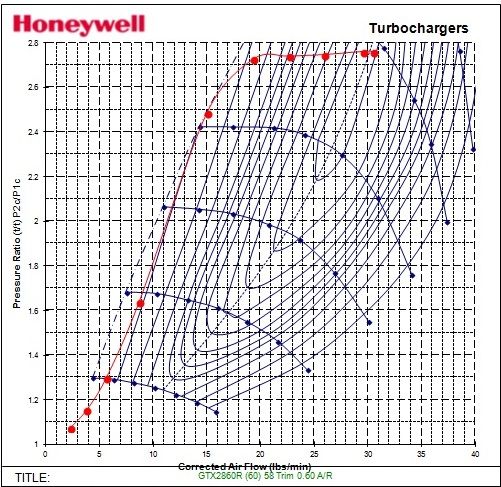

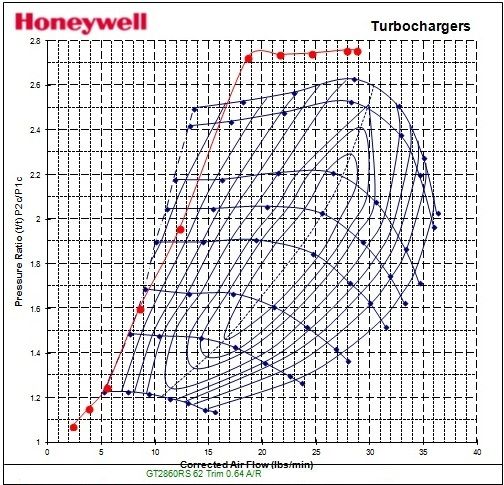

Which Garrett would you suggest for this setup? GTX2867R or GTX3067R ? These two are identical on compressor side, however the size of the turbine wheel is different. I am looking for AR .63 turbine side for both of them

The main parts (ATP site) for the two cases are:

GTX2867R -> GRT-TBO-187 & ATP-HSG-004 & ATP-WGT-023

GTX3067R -> GRT-TBO-260 & ATP-HSG-037 & ATP-FLS-075 or second option ATP-HSG-075 (but it is .72 A/R so may not be an option after all)

I am only interested in terms of performance, so do not judge by price. All of them will be internally wastegated and there is no restriction on choosing any of them.

Would the 3067 be much more laggy than 2867? Would my displacement be appropriate for the 3067?

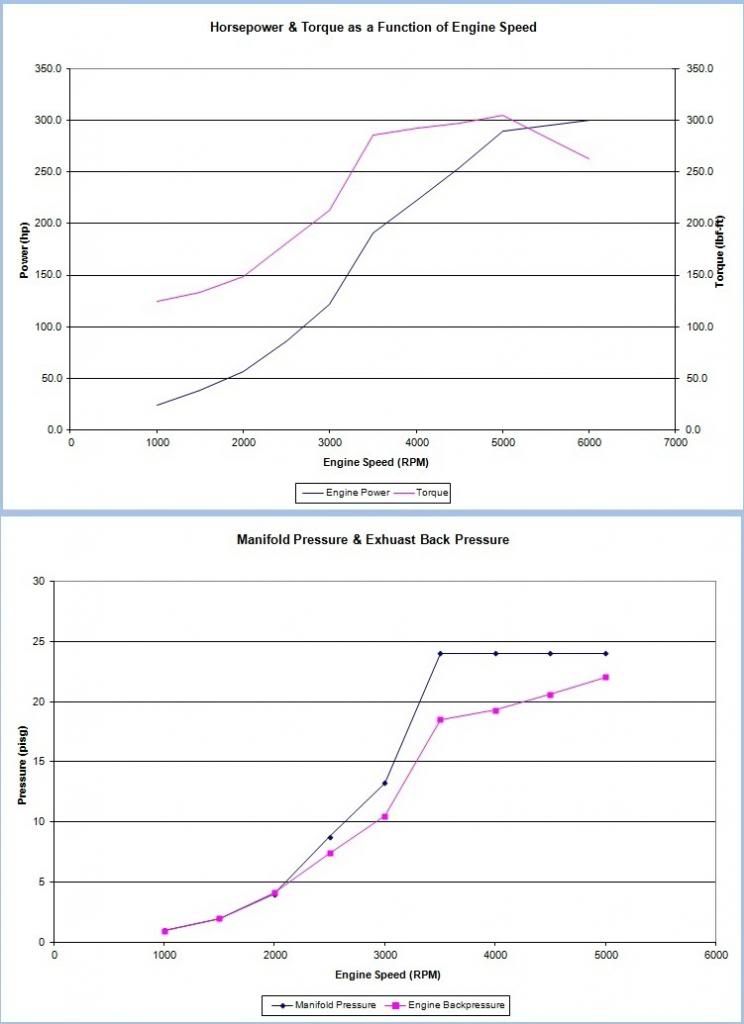

For my setup boost adviser on Garrett's site calculates pressure ratio of 2 and corrected air flow mid revs 18 and max revs 24. The goal is about 280-300hp .. maybe cant be achieved but .. its something to hope for

The question for turbo experts

:

: Which Garrett would you suggest for this setup? GTX2867R or GTX3067R ? These two are identical on compressor side, however the size of the turbine wheel is different. I am looking for AR .63 turbine side for both of them

The main parts (ATP site) for the two cases are:

GTX2867R -> GRT-TBO-187 & ATP-HSG-004 & ATP-WGT-023

GTX3067R -> GRT-TBO-260 & ATP-HSG-037 & ATP-FLS-075 or second option ATP-HSG-075 (but it is .72 A/R so may not be an option after all)

I am only interested in terms of performance, so do not judge by price. All of them will be internally wastegated and there is no restriction on choosing any of them.

Would the 3067 be much more laggy than 2867? Would my displacement be appropriate for the 3067?

For my setup boost adviser on Garrett's site calculates pressure ratio of 2 and corrected air flow mid revs 18 and max revs 24. The goal is about 280-300hp .. maybe cant be achieved but .. its something to hope for