Ttownthomas

New member

- Joined

- Feb 1, 2015

- Location

- Cary, NC

This is my first engine swap of any kind. I have been lurking and learning for a few months. I am not a tech but I work with some ASE Techs that will be helping me when I get stuck.

Ok. Here is the Volvo. It was acquired a couple of months ago. It is a 178,000 mile 1990 240. It is fairly rust free but it barely ran and was covered in mud and filth. It was destined for the scrap yard but it turned out to be pretty nice. It has been repainted by somebody at some point and since there is plenty of overspray I don't think it was a high end paint job. It has been thoroughly cleaned and runs well enough that I can drive it the 25 miles to the donor car.

Here is the donor car:

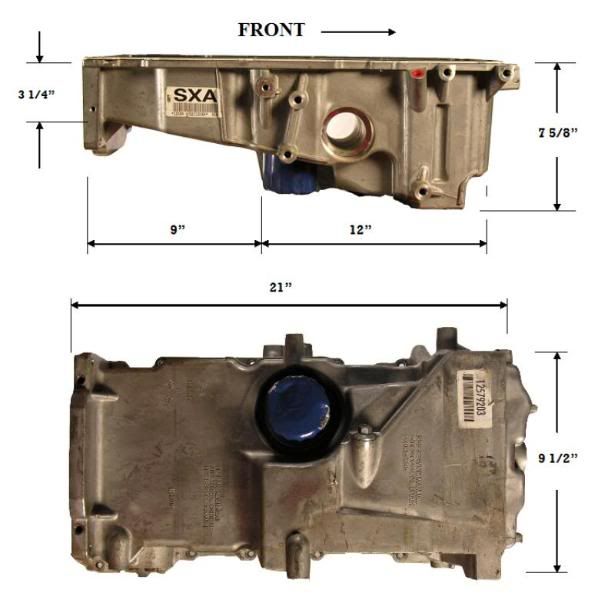

Its a 178,000 mile (coincidence) 2004 GMC Envoy XL. It has an aluminum Block LS that makes 290 Horsepower. The truck is totaled and I bought it an insurance auction. It did not have a key so I took a bit of a gamble on it. It turns out that it runs, gets up to temperature without overheating and has good oil pressure!

We will be using the Motor and the 60 series trans from this vehicle for the build

I will document the build here.

Ok. Here is the Volvo. It was acquired a couple of months ago. It is a 178,000 mile 1990 240. It is fairly rust free but it barely ran and was covered in mud and filth. It was destined for the scrap yard but it turned out to be pretty nice. It has been repainted by somebody at some point and since there is plenty of overspray I don't think it was a high end paint job. It has been thoroughly cleaned and runs well enough that I can drive it the 25 miles to the donor car.

Here is the donor car:

Its a 178,000 mile (coincidence) 2004 GMC Envoy XL. It has an aluminum Block LS that makes 290 Horsepower. The truck is totaled and I bought it an insurance auction. It did not have a key so I took a bit of a gamble on it. It turns out that it runs, gets up to temperature without overheating and has good oil pressure!

We will be using the Motor and the 60 series trans from this vehicle for the build

I will document the build here.

Last edited: