955IsAlive

New member

- Joined

- Apr 22, 2018

- Location

- MN

Setting aside the challenges of getting consistent E85 blends for a moment.

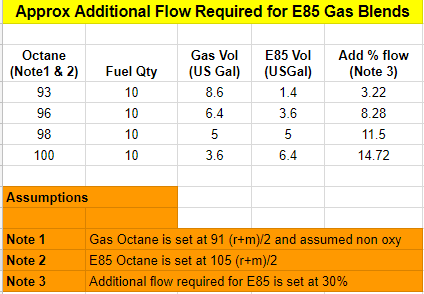

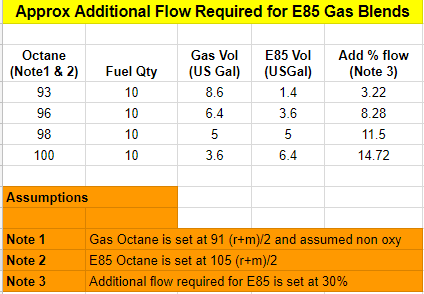

I made some calculations for the extra flow required based on desired octane for gas/E85 blends.

If you're already on a injector high duty cycle and fuel pressure with your system, this might be handy.

I made some calculations for the extra flow required based on desired octane for gas/E85 blends.

If you're already on a injector high duty cycle and fuel pressure with your system, this might be handy.