cleanflametrap

Well-known member

- Joined

- Sep 3, 2009

- Location

- near baltimore

I wouldn't be at all surprised if the CPS is the problem. I have had several 2-7-9s that had spark, fuel and good compression and wouldn't start and it turned out to be the CPS. I have learned to recognize the behavior. The first one I spent 10-30 minutes each session over a period of a week working on it and finally came to the conclusion it had everything it needed to run, yet wouldn't and threw another CPS in it. The 240 fired right up and ran perfect. The previous owner had spent $1,200 at various Volvo shops trying to solve the exact issue you are dealing with. They finally gave up and put it up for sale on craigslist. When I went to look at it, they went in for dinner and said "Let us know what you decide". It fired right up and I loaded it on the trailer. They came back out when I just finished chaining it down. They were surprised it started for me. Then, they elaborated on how it does that, runs perfect, then, strands them. I brought it home, unloaded it and didn't get back to it for a few days. It would not start, period. I could try until the battery was dead from cranking and nothing.

Recognize the behavior? Recognize it as "works now and then" with no correlation to anything, I say.

Here's how I came to the conclusion that our CPS is a difficult-to-make item of an early design. I say early, because I believe modern use of crank sensor systems do not sit on top with a wire exiting straight up in what is always a wet environment. Difficult to make because the reluctor core is wound with some seriously fine wire and then potted. I can't believe the manufacturing yield on these parts is anything over 85%, and that's just go/no-go test without any temperature stress.

This was a Bougicord sensor that drove me to these lengths. One I had replaced proactively after finding the original working sensor with the typical broken cable sheath inviting water to find its way into the iron core. Had all those recognizable "won't always start" symptoms. My better half's daily driver too.

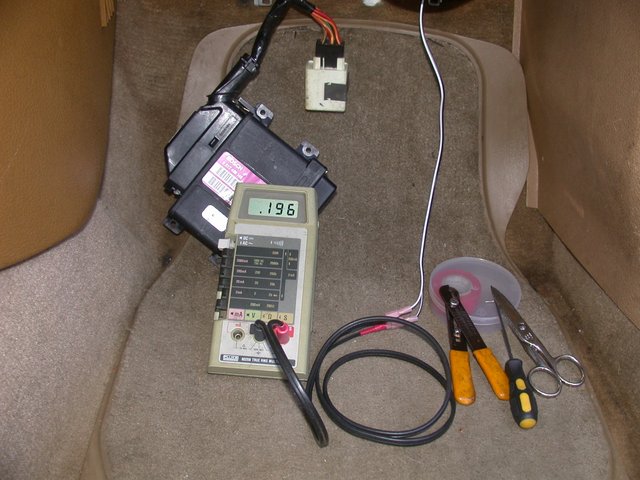

Scope or meter, you have to catch it when it isn't working. Temperature is probably the biggest influence on a connection poor enough to become a part-time semiconductor. I wired in a tap to watch it without disturbing any of the external connections which could have been the issue.

The meter isn't connected to measure AC volts -- that measurement has always struck me as inconclusive while cranking, with a digital meter. The meter is just measuring resistance, so it is disconnected until needed. The CPS, with all that fine wire, measures about 200 ohms and varies significantly with temperature. This is just an easy way to get a resistance reading without disturbing anything.

Aha. No start. Resistance nearly 1K.

The Bougicords were being sold for almost $80 at the time. Not only does the quality vary but the marketplace does as well. I found some aftermarket sensors for a price that begged me to experiment.

Used one and still have the second one as a spare. Still working well.

Bottom line for me? If in doubt just replace the sensor, but keep in mind, a new one is not necessarily a good one.