I can see how an independent Anti-Block System on a spaceship would be useful

Gimme a first start video already!!!!

That'll still be a while unfortunately

You are a lunatic... in the best way possible. An M113 would have been ridiculous enough for most, but not this madman.

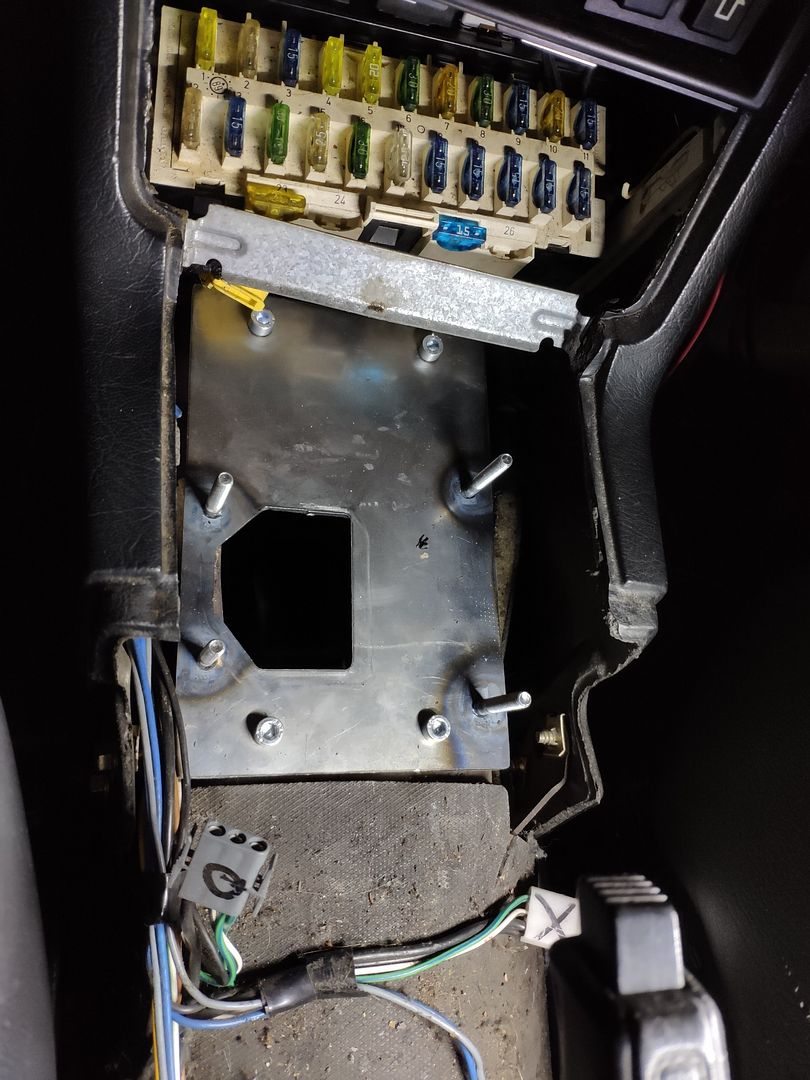

Did you replace the valvebody in addition to the TCU integration\bypass work for the paddle shifters?

Thanks! No need to change the valvebody. The only mod I did was drill out one of the oil passages to keep more pressure on the 3rd gear clutch pack during shifting from 3rd to 4th. The stand alone controller can't reduce power during shifting, so without that mod the rpm would flare up during the 3rd to 4th shift. It has full control over the stock valve body and torque converter etc and supports paddle shifters.

But if anyone is good at building below sea level, it's gonna be you guys

But if anyone is good at building below sea level, it's gonna be you guys