I can't think of anything down there I can't access as it is... all that is under there is the breather box which is easy to get to, and the starter which is accessed easiest from below regardless. I'd rather unbolt the manifold and the two AN fittings for the rail and remove it all complete than fight with 6 hose clamps and getting all the rubbers to seal back up again. It's not like you have to remove the fuel rail to get the intake manifold off...

The difference in our requirements for the manifolds appears to come down purely to the differences in the vehicles our engines are mounted in.

In the 240 there seems to be both more space and better access everywhere except perhaps around the brake servo area, and it might well be better for you to remove the manifold completely.

I had a minor problem at a meeting last year which necessitated getting down that side of the engine quickly, and it proved to be extremely difficult with the manifold in place, and for me removing the plenum and runner sections alone is far simpler that trying to get to the manifold fixings at the head.

On my car the starter motor can't be fitted from below either. My engine mount brackets are fabricated from steel and pick up on all six of the tappings into the block with the mounting rubbers between them and the engine cossmember. The steering rack lies directly behind that, with the anti-roll bar behind that again immediately ahead of the sump.

My engine sits so far back in the car that the passenger/ navigator footwell area is alongside the sump, with the chassis rail itself not far from its side and the clutch slave cylinder behind it.

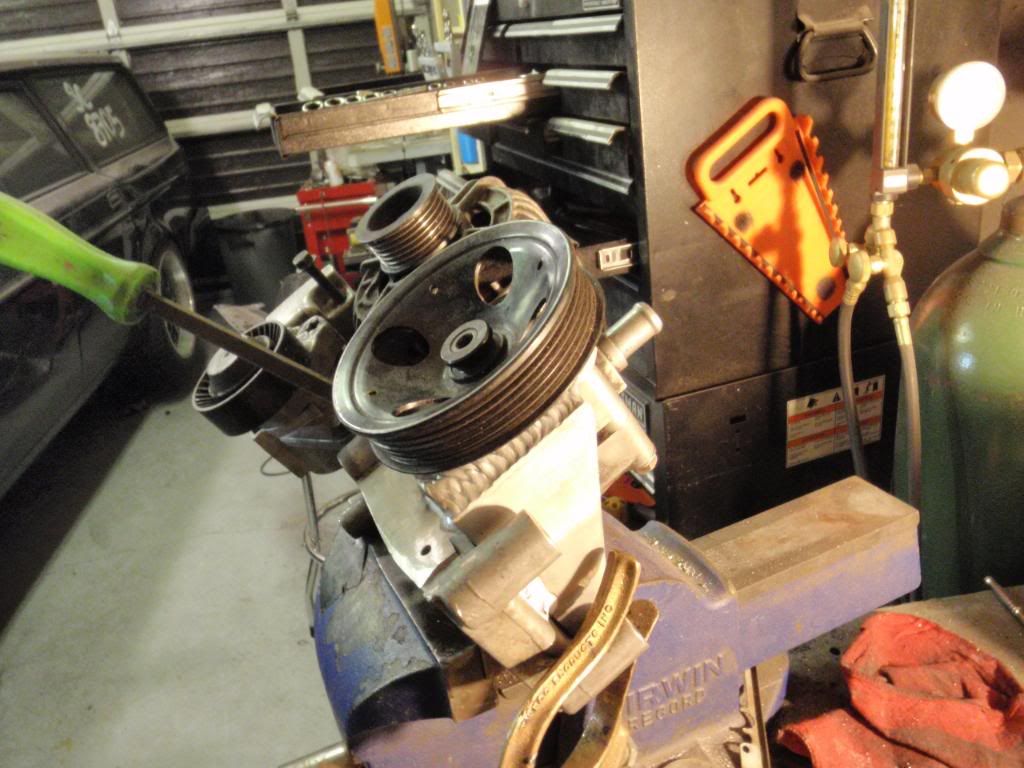

The currently fitted stock octopus manifold closes off almost all of the space to access from above, and even without a power steering pump in the way the breather and alternator (in addition to the mounting itself) denies any possibility of getting to the starter motor area from the front, never mind getting in to the manifold fixings. The large round octopus plenum with its lower brace to the engine mounting bracket in a simlar way to stock doesn't help the situation either.

After that last problem I decided that the manifold had to be changed to simplify servicing access, and I'd rather not disturb any of the fuel lines, connections, injectors, rail or wiring if possible to avoid any potential leaking seals and also help keep the service time down at meetings (this factor is less important at other times). The octopus manifold can't be removed without removing the strut brace either, which would be possible with a new one.

In making a new manifold I can take advantage of the stock rubbers to give me a point to easily split at, as well as changing to a front mounted throttle body to better suit connection to the intercooler, which should give me a really fast manifold removal time.

Your manifold, and the ones Nathan is currently fabricating for the redblock engines, is very similar to what I have in mind except for mounting it into the stock rubbers and bracing for both vibration and boost reasons back to the engine. There may not be any reason for anyone else to do this, but for me it seems like the best option.

I'd want to bracket the fuel pressure regulator to the 'fixed' part of the manifold, and look at making some quick release throttle cable arrangement that still incorporates the neccesary double return springs.

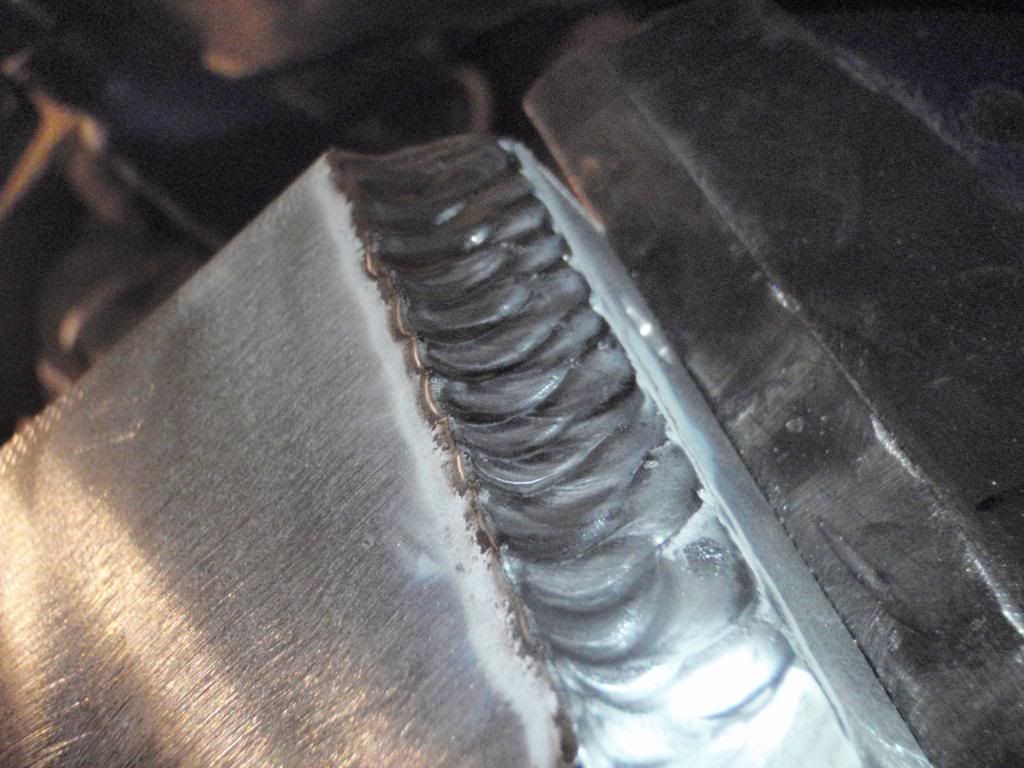

The resealing of these intake rubbers is a very good point though. Although they appear to be of the usual kind of synthetic material (unaffected by petrol) they do seem to suffer from hardening with age in the same way that I've seen happen on many similar motorcycle carburettor rubbers, and regular bending and flexing of them to fit the manifold runners probably won't do them any good as far as maintaining a seal under boost pressure. I'll start off with some brand new ones.

Still, a total of 7 jubilee clips, a couple of brace bracket bolts, a cable to unclip and possibly an intake tube to take off to remove the manifold should make servicing much easier than it is now!

They're even better now thought I think.

They're even better now thought I think.