-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 242, Now What Do I Do?

- Thread starter B2fkb0

- Start date

cwdodson88

Well-known member

- Joined

- Oct 27, 2011

- Location

- The Dalles, Oregon

looks good! The angled flange downpipe should be nice, planning to run 3" all the way back?

DD Ranch

Well-known member

- Joined

- Oct 21, 2010

- Location

- Tampa Bay, FL

*

Last edited:

Thanks Square D, your car is definitely an inspiration!

Hi CW Plan is 3" for 3' then transition to 2.5" TME system that came with the car.

Hey DD, I used por15 engine enamel on the intake; the 90+ came to me already coated with something unknown. It was in the trunk of a 244 my friend Slicknerd and I bought for $75 and drove home. I saw that mani and noticed it was machined flat and redrilled/tapped and coated so I grabbed it!

Hi CW Plan is 3" for 3' then transition to 2.5" TME system that came with the car.

Hey DD, I used por15 engine enamel on the intake; the 90+ came to me already coated with something unknown. It was in the trunk of a 244 my friend Slicknerd and I bought for $75 and drove home. I saw that mani and noticed it was machined flat and redrilled/tapped and coated so I grabbed it!

- Joined

- Jul 30, 2002

- Location

- Rockville, MD

Why did you mill your exhaust manifold flat if you are using a volvo turbine housing?

Matt86

New member

- Joined

- Nov 24, 2012

- Location

- Woodstock, GA

Awesome project! I wish I had the time and energy to tackle a project of this size. Also those Louvers are killer!

AndrewNance

Amateur hour!

- Joined

- Oct 24, 2011

- Location

- Winston-Salem, NC

Why did you mill your exhaust manifold flat if you are using a volvo turbine housing?

So you don't have to do it later?

Why did you mill your exhaust manifold flat if you are using a volvo turbine housing?

Hi Ben

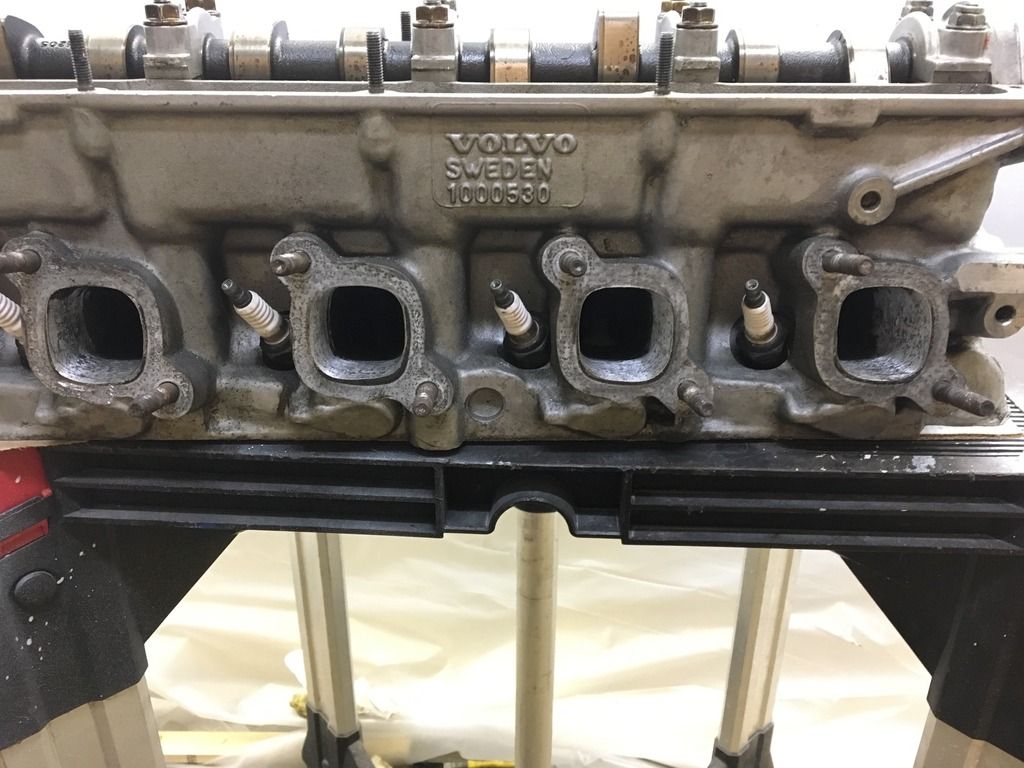

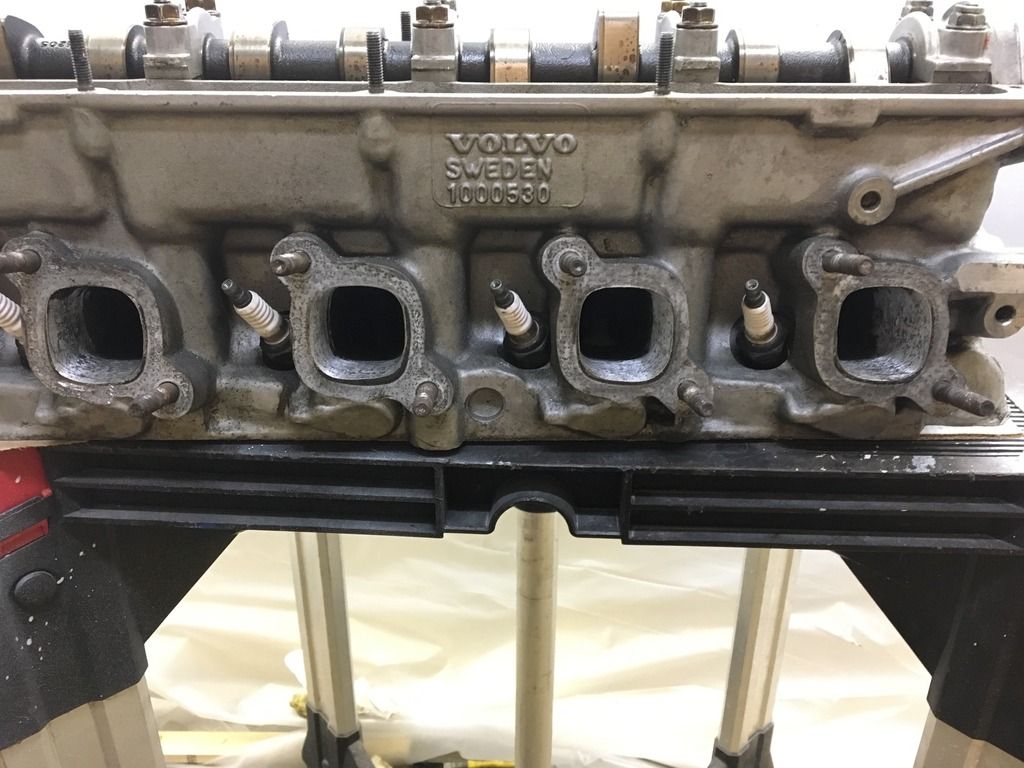

I got the 90+ manifold already milled. And it seems it was drilled and tapped as well (3/8-24 thread). I'm not sure as this is my first go around with redblocks! So much to learn.

Today I got a little more accomplished;

Removed the studs from the angle flange hot side and drilled the holes out (cobalt bit was a must, that high nickel cast is tough). Found that the upper rear stud and the hot side had a clearance issue

So I had to trim the flange to accommodate...

That was raw and it has now been smoothed out. Then a nice coat of cast iron grey from por 15

Next up is reclocking; the pins are out, the cchra is cleaned and I'll tig weld some mounting studs on the housing for the fasteners. Then the oil and water lines. Whew! I hope the 16T is worth it!

Also, thanks Matt for the kind words! Time is always an issue; I'm fortunate to have this summer off.

Robert is a great friend (transported those louvers from CA to MI) and we're lucky to have him in the Volvo community. He also has a 740 that he is building for his brother as a gift. So he likes all of them!

Robert is a great friend (transported those louvers from CA to MI) and we're lucky to have him in the Volvo community. He also has a 740 that he is building for his brother as a gift. So he likes all of them!

LC4CARL

Aero challenged

- Joined

- Sep 8, 2008

- Location

- Vancouver, WA

Unshroud = remove material at the gasket surface around the valve? And the larger chamber volume will lower the compression a bit?

cwdodson88

Well-known member

- Joined

- Oct 27, 2011

- Location

- The Dalles, Oregon

Unshroud = remove material at the gasket surface around the valve? And the larger chamber volume will lower the compression a bit?

Yes, you remove material from inside the combustion chamber around the valves increasing the CC of the chamber, lowering the compression.

Correct! The engine is a 95 squirter b230f (high compression NA), the head is off a 90 b230ft and was milled 2mm not too long ago. As I'm doing the plus T, I want to lower compression a bit. Anyone know a formula or have a simple method (my favorite) of figuring out how much I should take? With just removing a bit I figure I should be ok, but would rather know more about it. Also I'm gasket matching the head and the intake and exhaust manifolds. I've done v8 porting and some whiteblock porting. This is my first crack at a 530 head...

+Kardboard+

Chinese guy/Swedish rides

- Joined

- Aug 15, 2008

- Location

- Vancouver, Canada

This is awesome! Great work so far. Looking forward to updates.

Thanks Kardboard+! Finished the last chamber

And completed all of the exhaust ports. As many have said before, lots of opportunity here. So far about 5 hours into the porting. A lot of this time was spent cleaning the carbide burr of the aluminum. Finally used muratic acid and that works like a champ!

And completed all of the exhaust ports. As many have said before, lots of opportunity here. So far about 5 hours into the porting. A lot of this time was spent cleaning the carbide burr of the aluminum. Finally used muratic acid and that works like a champ!